Process Facilities

Frac Sands Project

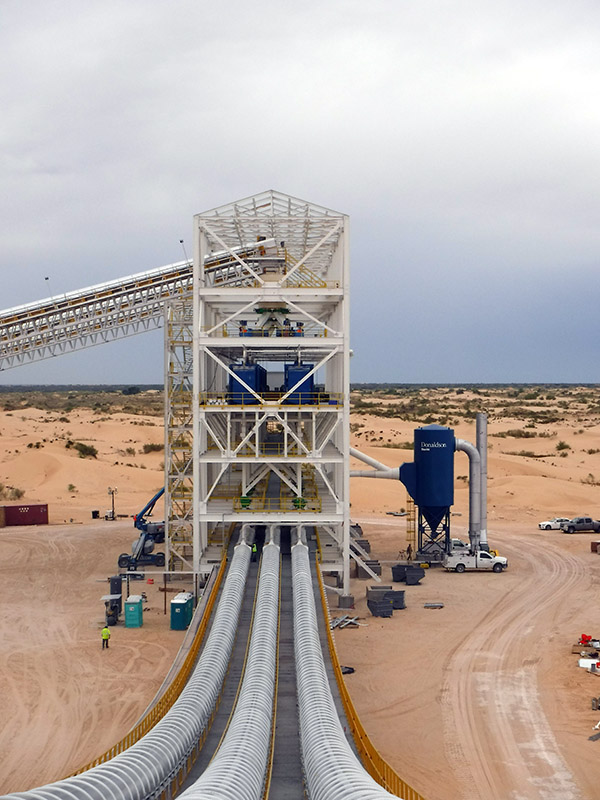

Millcreek provided detailed engineering design for a frac sand processing plant. The process included scalping, classification, dewatering, stockpiling and reclamation, drying, dry-screening and loadout. This facility was designed to have a wet processing facility from which wet sand of a desired size would be produced. The product was stockpiled, dried, and dry screened to produce desired size fraction products. This facility utilized scalping screen, hydrocyclones, high frequency screens, tailings filtration system, thickeners, dryers, a dry-screening system, conveyors and silos. The truck loadout system was capable of loading over 400 trucks per day.

Phosphate Facility

Millcreek provided basic engineering design which included designs to bypass the existing SAG mill and replace it with new screens, secondary crushing, tertiary crushing, and associated material handling equipment. The circuit was designed for 600 tph and continuous year-round operation. Energy efficiency and maintenance access were key design considerations for this project.

Gold Processing Facility

Lithium Carbonate

Millcreek completed the basic engineering design for lithium process plant. Our scope included the process flow diagrams, mass and energy balance. Full 3d model for the site, buildings and equipment. Construction specifications, equipment specifications and fabricated material take-offs. Capital and operating costs with 10% accuracy and project schedule.