Bulk Material Handling

Millcreek designs and delivers bulk material handling systems across a broad range of commodities. We handle the most challenging materials such as sticky hard to handle clay, bauxite or gypsum, dusty coal or alumina, corrosive fertilizers and salts, and abrasive silica rock or DRI.

Bulk Material Handling Capabilities

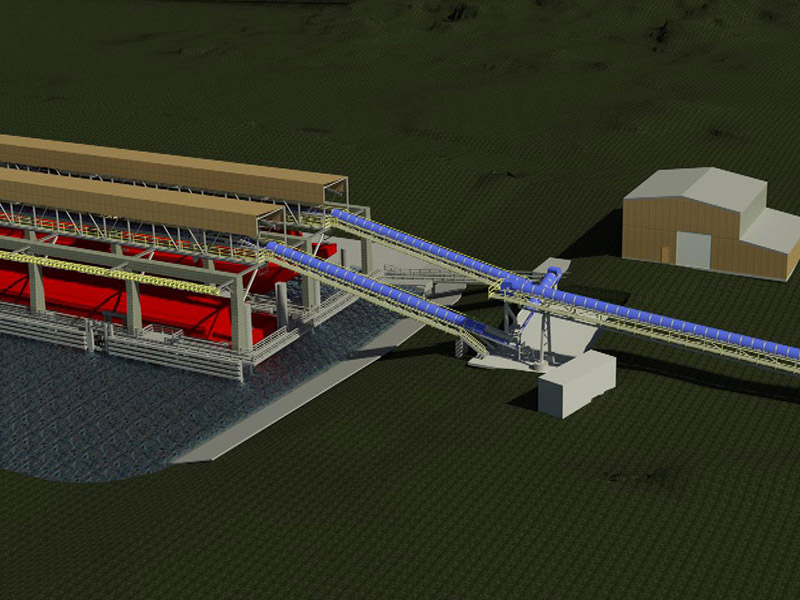

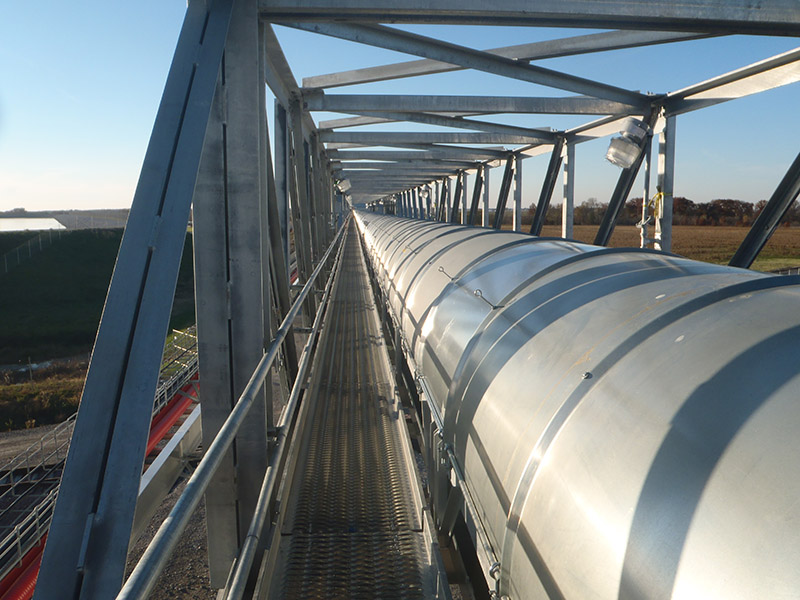

- Conveying

- Stacking and reclaiming

- Crushing and screening

- Blending

- Weighing and sampling

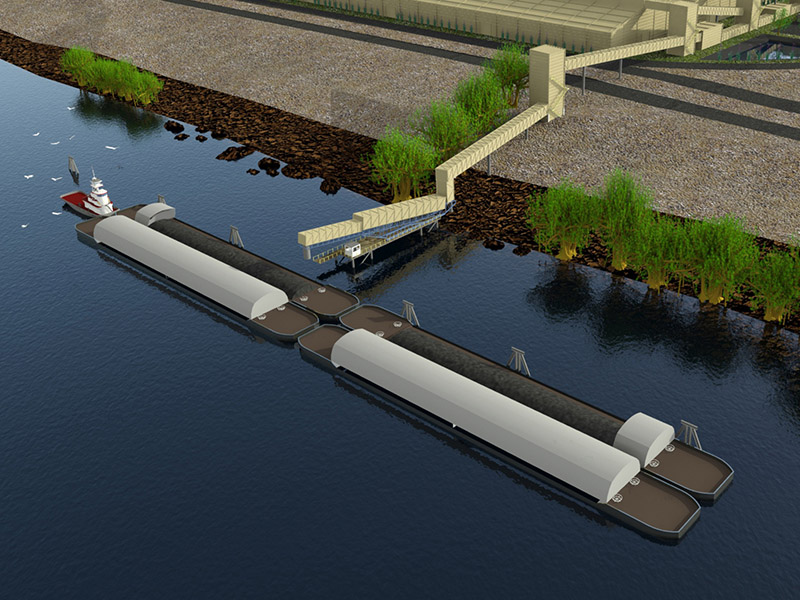

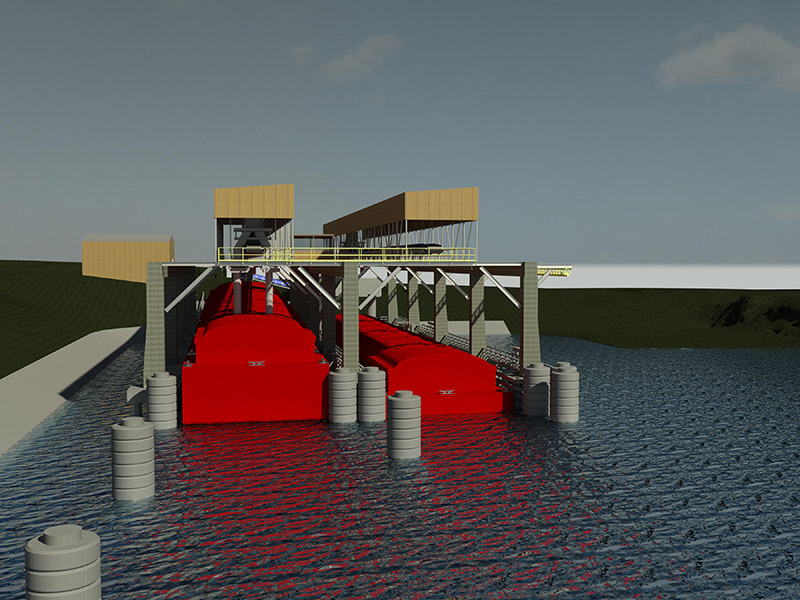

- Truck, rail, barge, and ship loading

We have particular expertise in transfer, chutework, and skirtboard designs.

Our belt and conveyor designs are innovative and provide effective material handling solutions, including long distance, high capacity overland conveyors with vertical and horizontal curves, re-gen, and tube conveyors.